The Essential Guide to Wire and Cable Machinery: Enhancing Electrical Manufacturing Efficiency

Release time:

2025-03-03

Wire and cable machinery plays a pivotal role in the production of electrical and electronic products, enabling manufacturers to create high-quality wires and cables that meet various industry standards. This specialized machinery encompasses a range of equipment designed for different manufacturing processes, including wire drawing, cabling, insulation, and testing. At the heart of wire and cable

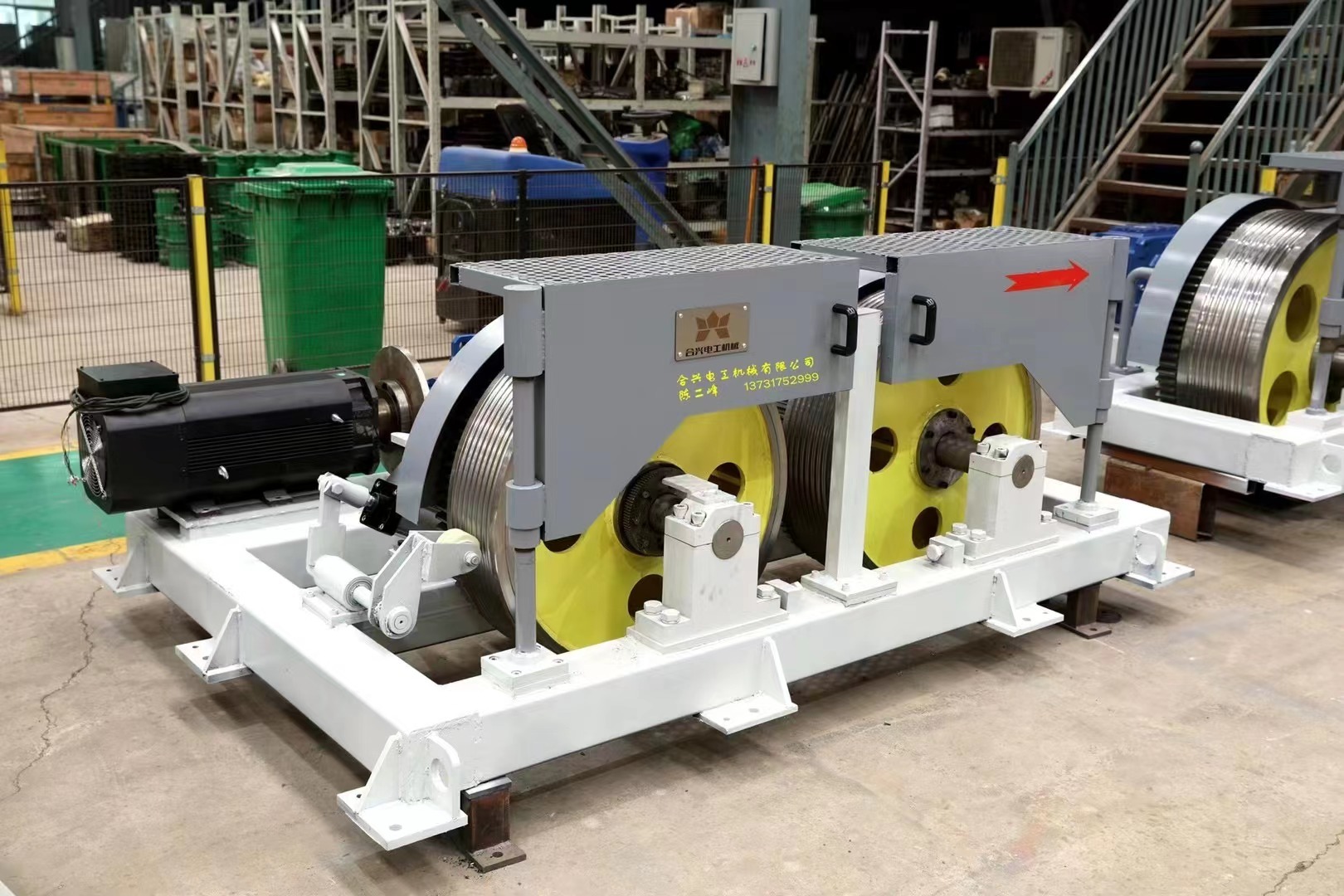

At the heart of wire and cable machinery is the wire drawing machine, which reduces the diameter of metal wire through a series of dies. This process not only improves the wire's mechanical properties but also prepares it for subsequent steps. Following wire drawing, the cabling machinery takes center stage, twisting multiple wires together to form cables. This stage is crucial as the configuration of wires affects the cable's performance and durability.

Insulation is another critical process in wire and cable production. Insulation machinery applies materials to the wire to protect it from environmental factors, mechanical damage, and electrical interference. This step is vital in ensuring safety and functionality in electrical applications. Advanced insulation machines often use thermoplastics and thermosetting materials that enhance the cables' resistance to heat, chemicals, and abrasion.

Testing equipment is equally essential in the manufacturing process. Quality control is paramount, and specialized testing machines ensure that the wires and cables meet stringent electrical and physical specifications. These machines help identify any defects or weaknesses in the products before they reach the market, thereby safeguarding manufacturers from costly recalls and reputational damage.

Automation is increasingly becoming a trend in wire and cable machinery. Advanced technologies such as robotics and artificial intelligence are being integrated into manufacturing processes to enhance productivity and precision. Automated systems can significantly reduce labor costs and minimize human errors, leading to higher output rates and better product quality.

Moreover, the wire and cable industry is experiencing a shift towards sustainable manufacturing practices. Machinery is being designed to reduce waste, energy consumption, and environmental impact. Manufacturers are increasingly investing in technology that promotes recycling and the use of eco-friendly materials in their production processes.

In summary, wire and cable machinery is essential for the efficient and reliable manufacturing of electrical products. From wire drawing to insulation and testing, each step in the production process is supported by specialized machinery that ensures the highest quality standards. As the industry evolves, advancements in automation and sustainability will continue to shape the future of wire and cable manufacturing, making it more efficient, cost-effective, and environmentally friendly. Understanding these processes and technologies is crucial for anyone involved in the electrical manufacturing sector.

TAG:

Recommend News

HEXING CABLE MACHINERY

TEL: +86-317-3601666, +86-317-3236119

FAX: +86-317-3618408

E-MAIL: china@hbhxdg.cn

E-MAIL: hbhxdg@gmail.com

WEB: http://www.hbhxdg.cn

ADD: Baoantun Industrial Zone, Hejian City, Hebei Province