The Advantages and Applications of Automatic Wire Twisting Machines

Release time:

2025-06-17

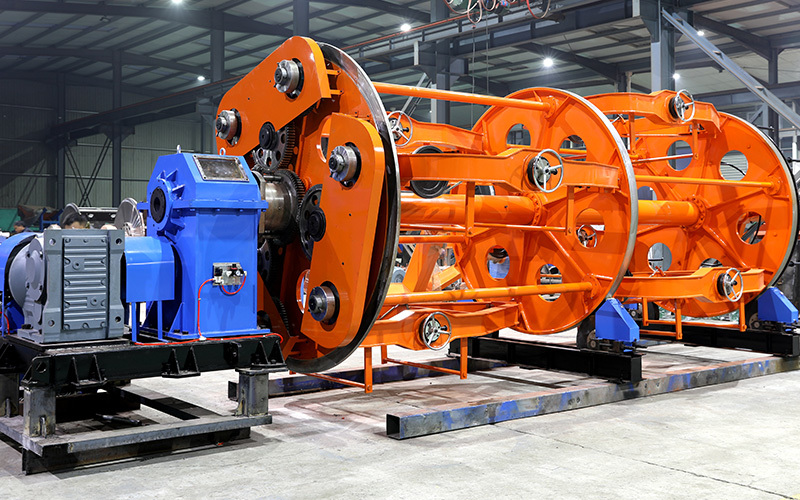

Automatic wire twisting machines are an integral part of the electrical and electronics manufacturing sector, particularly in the production of various wire harnesses and cable assemblies. These machines are designed to streamline the twisting process, which involves intertwining multiple wire strands to create a robust and efficient connection. The use of automatic wire twisting machines offers n

One of the primary benefits of using an automatic wire twisting machine is increased productivity. Traditional manual twisting methods can be time-consuming and labor-intensive. By automating this process, manufacturers can achieve higher output levels while reducing the time required to produce each unit. This efficiency is particularly valuable in industries where large volumes of cable assemblies are needed, such as automotive, telecommunications, and consumer electronics.

In addition to boosting productivity, automatic wire twisting machines also improve consistency and quality. Manual processes are prone to human error, which can lead to variations in the twisting tension and overall wire integrity. An automatic machine ensures uniformity in the twisting process, resulting in consistent quality across all produced wires. This reliability is critical for applications that require high standards of performance and safety, such as in electrical wiring for vehicles or complex electronic devices.

Moreover, the integration of advanced technologies into automatic wire twisting machines has further enhanced their capabilities. Many modern machines come equipped with programmable settings, allowing operators to customize the twisting parameters based on specific requirements. This adaptability makes it easier for manufacturers to switch between different wire types and configurations without significant downtime, thereby maximizing operational flexibility.

From a cost perspective, the use of automatic wire twisting machines can lead to substantial savings. By minimizing labor costs and reducing material waste through precise twisting, manufacturers can improve their overall profit margins. Furthermore, the long-term reliability of these machines often results in lower maintenance costs, making them a worthwhile investment for businesses looking to optimize their production processes.

In summary, automatic wire twisting machines play a crucial role in the electrical and electronics manufacturing landscape. Their ability to enhance productivity, ensure consistent quality, and reduce operational costs makes them an essential tool for manufacturers in this field. As technology continues to advance, the capabilities of these machines are likely to expand, further solidifying their importance in modern manufacturing practices. Adopting automatic wire twisting machines can provide manufacturers with a competitive edge in a rapidly evolving marketplace.

TAG:

Previous

Previous Page:

Recommend News

HEXING CABLE MACHINERY

TEL: +86-317-3601666, +86-317-3236119

FAX: +86-317-3618408

E-MAIL: china@hbhxdg.cn

E-MAIL: hbhxdg@gmail.com

WEB: http://www.hbhxdg.cn

ADD: Baoantun Industrial Zone, Hejian City, Hebei Province