Uncovering the Secrets of Affordable Cable Wire Manufacturing Machines

Release time:

2025-08-01

Uncovering the Secrets of Affordable Cable Wire Manufacturing Machines Introduction to Cable Wire Manufacturing Machines Cable wire manufacturing is an essential process in various industries, ranging from telecommunications to electrical engineering. Understanding the machinery used in this process not only improves production efficiency but also ensures quality in the final products. In this art

Uncovering the Secrets of Affordable Cable Wire Manufacturing Machines

Introduction to Cable Wire Manufacturing Machines

Cable wire manufacturing is an essential process in various industries, ranging from telecommunications to electrical engineering. Understanding the machinery used in this process not only improves production efficiency but also ensures quality in the final products. In this article, we will delve into the world of cable wire manufacturing machines, focusing on affordability without compromising quality.

The Importance of Choosing the Right Cable Wire Manufacturing Machine

When it comes to manufacturing cable wire, selecting the appropriate machinery can significantly impact the production process. Here are several reasons why the right machine matters:

1. Cost Efficiency

Investing in affordable yet efficient machinery can reduce overhead costs. By choosing the correct machine, manufacturers can save money on energy consumption, maintenance, and repairs.

2. Enhanced Production Speed

High-performance machines can increase production speed, enabling manufacturers to meet demand without sacrificing quality.

3. Consistent Quality

Quality is paramount in cable manufacturing. The right machine ensures that each wire produced meets industry standards for safety and performance.

4. Flexibility in Production

Modern cable wire manufacturing machines often come equipped with features that allow for versatility in production, accommodating different wire sizes and materials.

Types of Cable Wire Manufacturing Machines

Understanding the different types of cable wire manufacturing machines available on the market can help in making an informed decision. Here are some commonly used machines:

1. Wire Drawing Machines

These machines reduce the diameter of wire by pulling it through a series of dies. They are essential for achieving the desired thickness and tensile strength in cable wire.

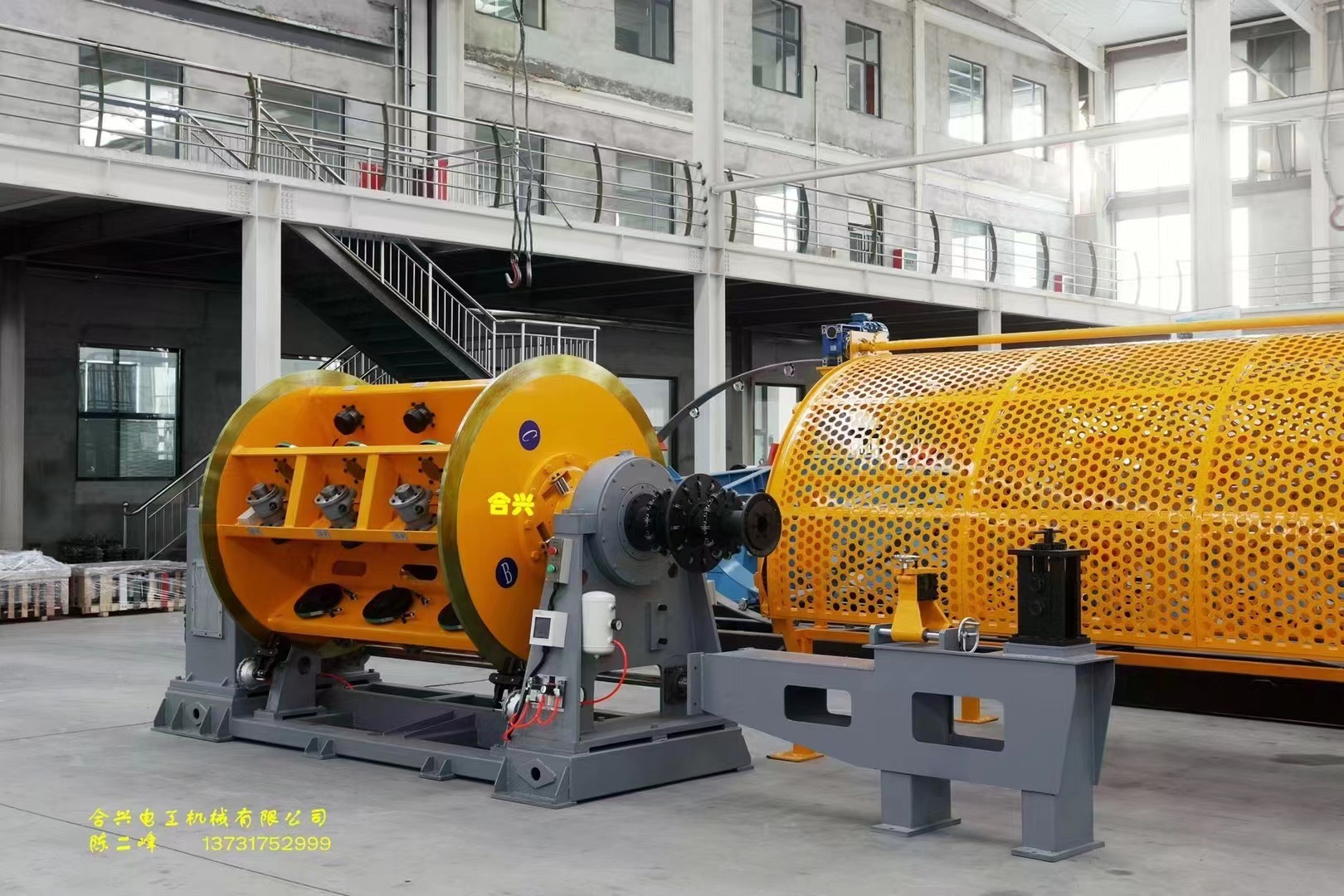

2. Stranding Machines

Stranding machines twist multiple wire strands together to form a cable. This process is crucial for enhancing the cable's flexibility and strength.

3. Insulation Machines

Insulation machines apply protective coatings to the wire, enhancing safety and durability. This is a critical step in the manufacturing process, especially for electrical cables.

4. Sheathing Machines

These machines apply an outer layer of protection to the completed cable, which is essential for shielding against environmental factors and electrical interference.

5. Testing and Quality Control Equipment

Quality control is vital in the manufacturing process. Testing machines ensure that the produced cables meet the required specifications and safety standards.

Factors to Consider When Selecting Affordable Cable Wire Manufacturing Machines

Choosing the right machine involves considering several factors:

1. Production Volume Needs

Assessing the daily production volume required will help in selecting a machine that meets those needs without overspending.

2. Material Compatibility

Ensure that the chosen machine can handle the types of materials you plan to use for your cables. Different machines are designed for different materials, such as copper, aluminum, or fiber optics.

3. Technology and Features

Modern machines often come with advanced technology, such as automation and digital controls, which can significantly enhance efficiency and precision.

4. Maintenance and Support

Consider the manufacturer's reputation for customer support and the availability of spare parts. Affordable machines may still require regular maintenance, so a reliable support system is essential.

Top Affordable Cable Wire Manufacturing Machines in the Market

Here are some notable affordable machines that are making waves in the cable manufacturing industry:

1. XYZ Wire Drawing Machine

The XYZ Wire Drawing Machine is known for its robustness and efficiency. It offers a wide range of wire sizes and is compatible with various materials, making it suitable for diverse production needs.

2. ABC Stranding Machine

This machine is celebrated for its user-friendly interface and high production speed. It is ideal for manufacturers looking to produce high-quality stranded cables quickly.

3. DEF Insulation Applicator

The DEF Insulation Applicator provides excellent insulation application precision. Its compact design and affordability make it a favorite among small to medium-sized manufacturers.

Strategies for Maximizing Efficiency in Cable Wire Manufacturing

Once you have selected the right machines, implementing strategies to maximize efficiency is the next step:

1. Regular Maintenance

Routine checks and maintenance can prevent breakdowns and prolong the lifespan of your machines. A well-maintained machine operates more efficiently.

2. Staff Training

Investing in staff training ensures that operators can utilize the machinery to its fullest potential, leading to higher productivity and lower error rates.

3. Production Planning

Effective production planning can help in managing resources better. Utilizing software for scheduling and inventory management can streamline operations.

4. Energy Management

Implementing energy-efficient practices can not only reduce costs but also contribute to a more sustainable manufacturing process.

Case Studies: Success Stories in Affordable Cable Wire Manufacturing

Examining case studies provides valuable insight into how manufacturers have optimized their processes using affordable cable wire manufacturing machines.

1. Case Study: Global Cable Co.

By investing in a combination of XYZ Wire Drawing and DEF Insulation Applicator machines, Global Cable Co. increased its production efficiency by 40%, showcasing the power of selecting the right equipment.

2. Case Study: Local Electric Solutions

Local Electric Solutions adopted a comprehensive maintenance and staff training program, resulting in a 30% reduction in downtime. This exemplifies the importance of operational strategies alongside machinery selection.

Future Trends in Cable Wire Manufacturing

As technology evolves, so does the machinery used in cable wire manufacturing. Here are some trends to watch:

1. Automation

Automated machinery is becoming increasingly prevalent, reducing labor costs and increasing precision in production.

2. Eco-Friendly Machines

With growing concerns about environmental sustainability, manufacturers are developing machines that reduce waste and energy consumption.

3. Smart Manufacturing

The integration of IoT (Internet of Things) in manufacturing machines allows for real-time monitoring and data analysis, enhancing decision-making processes.

FAQs about Affordable Cable Wire Manufacturing Machines

1. What should I look for in an affordable cable wire manufacturing machine?

When selecting a machine, consider production volume, material compatibility, technology features, and maintenance support.

2. Are affordable machines reliable for high-volume production?

Many affordable machines are designed to handle significant production volumes while maintaining quality, but it's crucial to choose one that fits your specific needs.

3. How can I improve the efficiency of my cable wire manufacturing process?

Implement strategies such as regular maintenance, staff training, effective production planning, and energy management.

4. What types of materials can be used in cable wire manufacturing?

Common materials include copper, aluminum, and fiber optics, each requiring different machines and processes for manufacturing.

5. What is the future of cable wire manufacturing technology?

Expect to see trends in automation, eco-friendly machines, and smart manufacturing solutions that enhance production efficiency and sustainability.

Conclusion

Investing in affordable cable wire manufacturing machines can dramatically enhance production efficiency without sacrificing quality. By understanding the types of machines available, considering crucial factors, and implementing strategies for improvement, manufacturers can position themselves for success in this competitive industry. As technology continues to evolve, staying informed about the latest trends will ensure that you remain at the forefront of cable wire manufacturing.

TAG:

Previous Page:

Recommend News

HEXING CABLE MACHINERY

TEL: +86-317-3601666, +86-317-3236119

FAX: +86-317-3618408

E-MAIL: china@hbhxdg.cn

E-MAIL: hbhxdg@gmail.com

WEB: http://www.hbhxdg.cn

ADD: Baoantun Industrial Zone, Hejian City, Hebei Province