Exploring the Benefits of Durable Automatic Wire Twisting Machines for Electrical Manufacturing

Release time:

2025-08-06

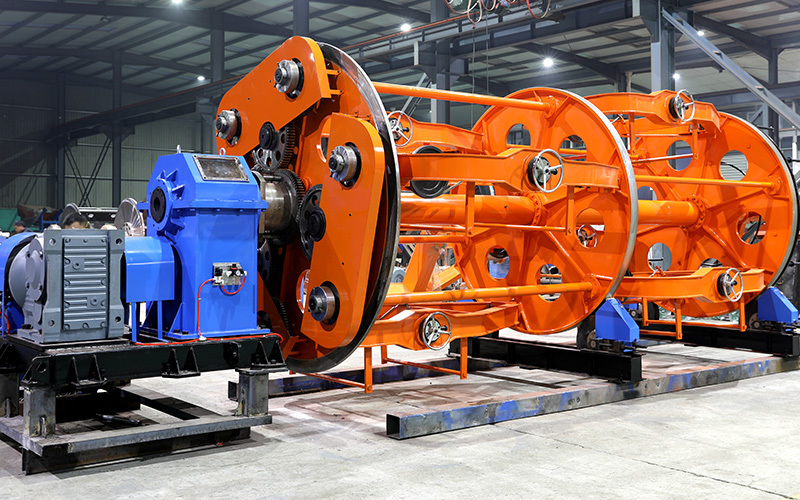

In the rapidly evolving world of electrical manufacturing, the need for efficient, reliable, and durable machinery is paramount. Among the key equipment that plays a significant role in this sector is the durable automatic wire twisting machine. These machines are essential for producing high-quality twisted wire products, widely used in various applications from automotive to consumer electronics

One of the primary benefits of using a durable automatic wire twisting machine is its efficiency. These machines are designed to handle large volumes of wire twisting with precision and speed, significantly reducing production times. Unlike manual twisting methods, which can be labor-intensive and time-consuming, automatic machines streamline the process, allowing manufacturers to meet growing demands without compromising on quality.

Reliability is another crucial factor to consider when investing in a wire twisting machine. A durable automatic wire twisting machine is built to withstand rigorous daily operations, minimizing downtime due to mechanical failures. This reliability ensures a consistent output quality, which is vital in maintaining the integrity of the electrical products being produced. Manufacturers can trust these machines to perform consistently, thus enhancing overall productivity.

Moreover, the technological advancements integrated into modern automatic wire twisting machines contribute to their durability and effectiveness. Features such as programmable controls, advanced sensors, and real-time monitoring systems allow for greater flexibility in production. These technologies enable operators to adjust twisting parameters according to specific requirements, ensuring that each batch meets the desired specifications. This adaptability is particularly valuable in an industry that often demands customization to cater to diverse client needs.

In addition to operational efficiency, investing in a durable automatic wire twisting machine can also lead to cost savings in the long run. While initial acquisition costs may be higher than manual alternatives, the reduction in labor costs, increased production speed, and lower maintenance requirements often justify the investment. Furthermore, the quality of twisted wires produced by these machines can lead to fewer defects and reworks, ultimately resulting in lower overall operational costs.

Environmental considerations are also becoming increasingly important in manufacturing processes. Durable automatic wire twisting machines can be designed with energy-efficient features that reduce power consumption during operation. This not only contributes to cost savings but also aligns with the growing emphasis on sustainable manufacturing practices.

In summary, the durability, efficiency, and advanced technology of automatic wire twisting machines make them an indispensable asset in the electrical manufacturing industry. By adopting these machines, manufacturers can enhance productivity, ensure consistent quality, and achieve cost savings, all while meeting the evolving demands of the market. As the industry continues to innovate, the role of durable automatic wire twisting machines will only become more critical in shaping the future of electrical product manufacturing.

TAG:

Recommend News

HEXING CABLE MACHINERY

TEL: +86-317-3601666, +86-317-3236119

FAX: +86-317-3618408

E-MAIL: china@hbhxdg.cn

E-MAIL: hbhxdg@gmail.com

WEB: http://www.hbhxdg.cn

ADD: Baoantun Industrial Zone, Hejian City, Hebei Province